AMADA WELD TECH New proccessing technology

Active Heat control

Heat process evolution of laser

The new fuction implements much stable process by controlling laser power based on processing area!

~It's effective not only welding but also hardening, laser soldering and plastic welding~

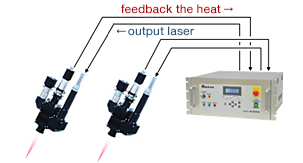

What's the Active Heat Control?

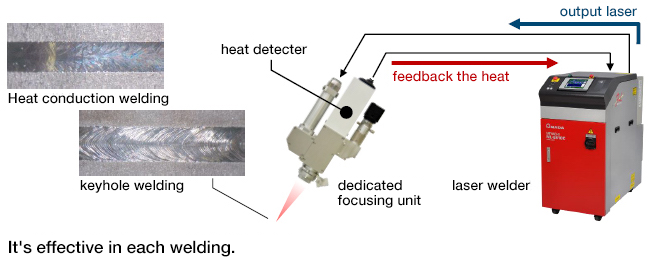

It's the new function to controll laser output automatically based on the heat of proccessing area. It enables to controll laser output to get the heat that is already set up, by doing feedback to laser welder through the dedicated focusing unit.

It's different from previous function* that is based on laser output in a laser welder, and the new function enables to controll laser output according as workpiece condition based on processing area.

It's suitable for welding, hardening and other application that heat control is important.

*Real-time power feedback

Superiority of Active Heat Control 1

Laser welding is much stable

Margin for Z-axis changing of focal point is increased

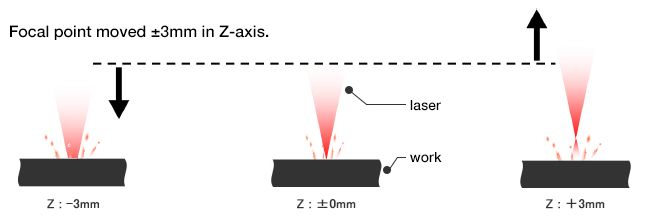

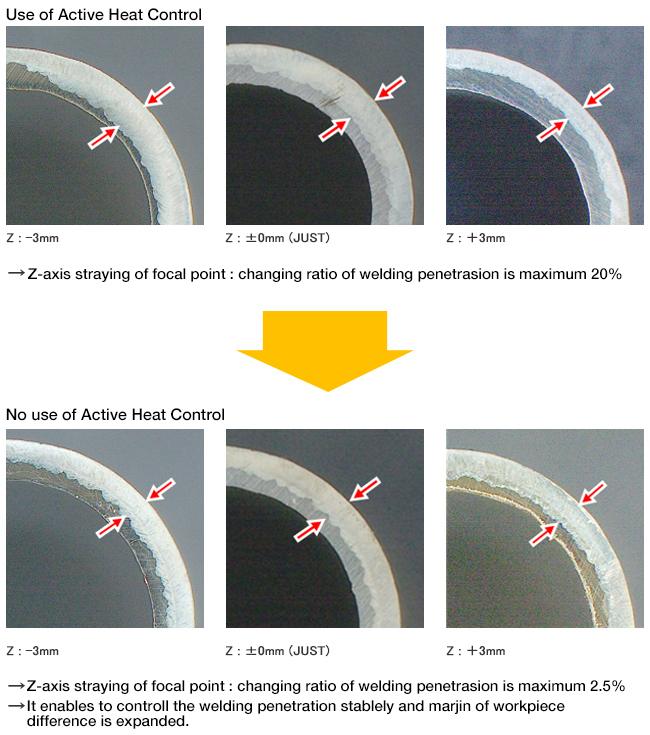

Usually, laser proccess is done in focal point. In case of laser welding also, welding quality can be changed if the Z-axis is not stable.

At this evaluation, it's clear that the new function enables to controll welding penetration stabely and expand marjin, even if Z-axis goes up and down.*

*It's not guarantee of welding quality.

How to evaluate (stability of Z-axis is need in previous function)

Evaluation result

Recommended laser welders are here!

Fiber laser welder

ML-6810C

Fiber laser welder

MF-C300A-SF/C500A-SF/C1000A-S

Superiority of Active Heat Control 2

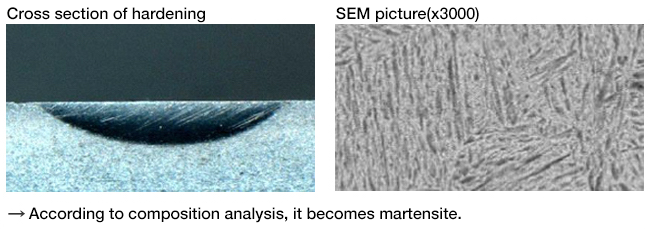

It's suitable for laser hardening

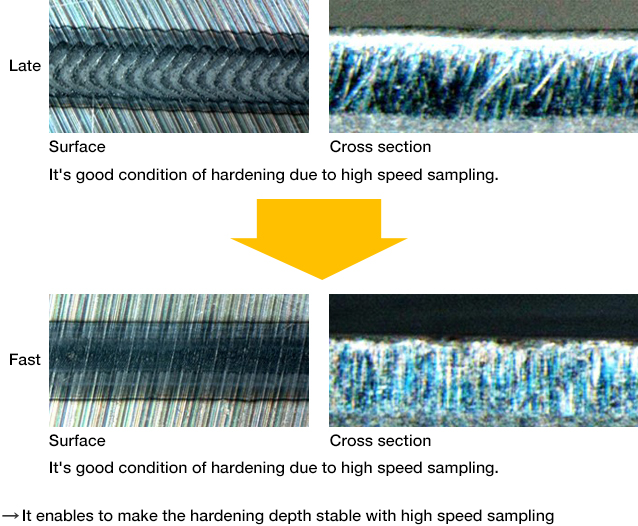

It enables to make the hardening depth stable with high speed sampling

The new function controls laser output to maintain the heat stablely in proccessing point.

According to the feature, it's effective in laser hardening that needs to maintain suitable and insoluble temperature.

In case of previous function, heating of jig because of repeatable proccessing and heat conduction into workpiece are generated. In such cases, workpiece can be melt due to over heat.

Because it's impossible to maintain the suitable heat for the previous function.

How to evaluate and the result

■Configuration of the product

- Laser welder: ML-6810C

- Width of hardening: approx. 2mm

- Material: S50C

■Sampling speed

Recommended laser welders for hardening are here!

Fiber laser welder

ML-6810C

Superiority of Active Heat Control 3

It's suitable for laser soldering

Multi-points and double-line soldering is stable due to the new function and special optical component.

The new function is effective in case of soldering that the melting temperature is lower than metals.

It avoids over-heat and implements stable soldering, because it detects surface temperature of solder on same axis and enables to controll with suitable output.

And multi-points soldering is poissible due to special optical component. Please check the video.

How to evaluate and the result

■Configuration of the product

- Laser welder: ML-5020AW

- Workpiece: IC lead (4 points and double line, at the same time)

Recommended laser welders for soldering are here!

Contact for repair/recovery of AMADA Micro Welding products and our corporate activities.